Infrastructure

for high-precision requirements

Advanced technologies are essential for top-tier precision work. Our machine park is modernised on an ongoing basis and, combined with the know-how of our dedicated team, paves the way for satisfied clients in Switzerland and abroad. Keller Precision relies on CNC 5-axis simultaneous milling and milling/turning centres, CNC 6-sided turning/milling centres and 3D coordinate measurement machines for demanding tasks. The measurement room, which is certified according to quality class 3 in accordance with VDI/VDE 2627, is at the heart of our top-quality precision work.

3D measurement room

for maximum process accuracy

Our measurement room is at the heart of our precision work. Kept at a constant temperature of 20±0.5 °C and a maximum humidity of 55 percent, we guarantee the most accurate measurement results to comply with minimal tolerances. Our measurement room meets all the requirements for quality class 3 according to VDI/VDE 2627, which also includes ISO 8 filters for particle retention and a guaranteed overpressure of 10 Pascal at all times. The airlock principle applies to the sectional doors, while a vibration-isolated, separate foundation ensures stable and reproducible measurement results. This allows us to meet the strictest quality standards and guarantee the highest measurement accuracy.

Specifications of the measurement room

- Measurement range up to X = 2,000, Y = 3,700, Z = 1,500 mm

- Quality class 3 measurement room according to VDI/VDE 2627

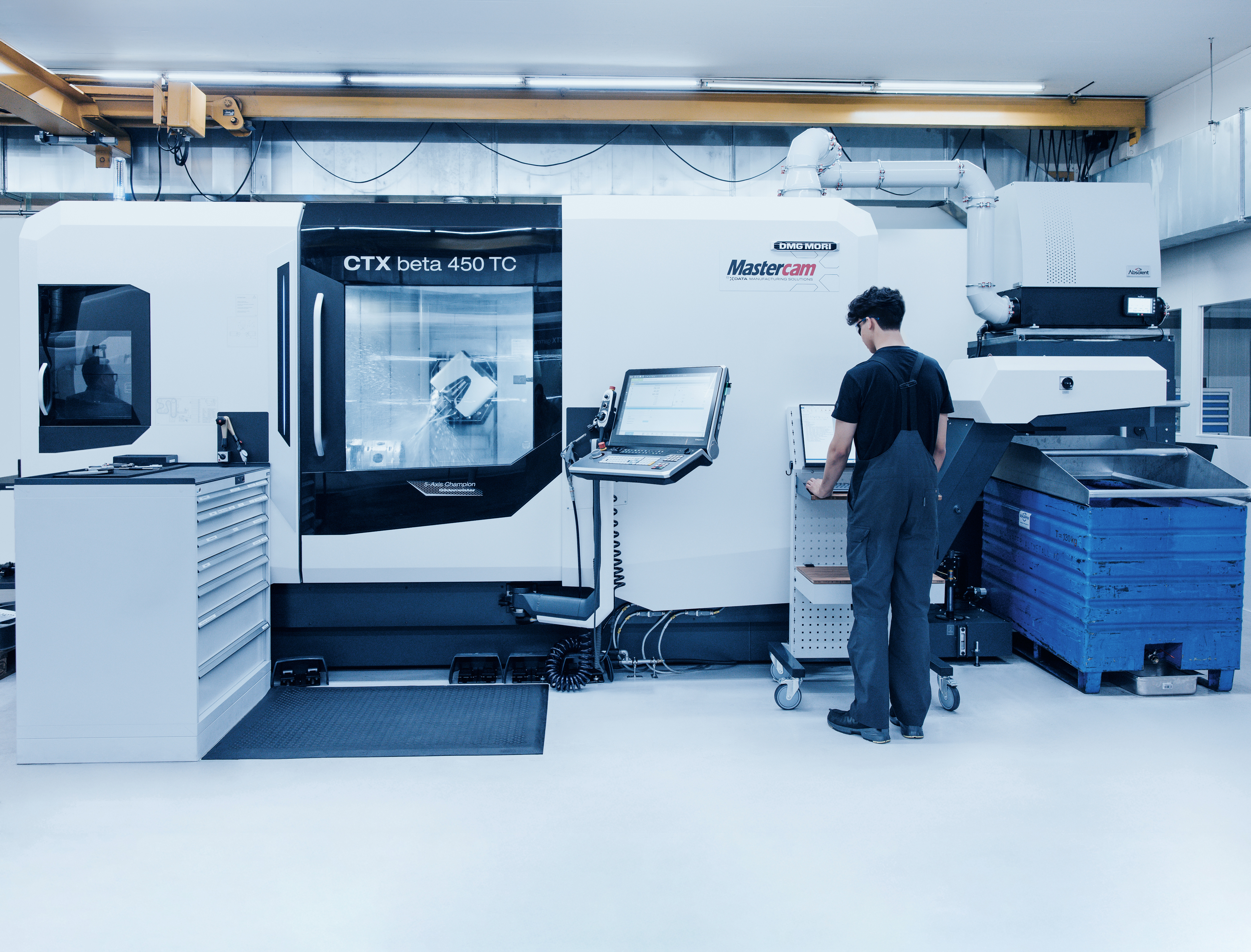

Turning centres and

turning/milling centres

We use our versatile turning centres and turning/milling centres to handle ultra-demanding manufacturing tasks. High-precision turning operations are combined with milling work to meet even the most complex geometries and tightest tolerances.

CNC 6-sided turning/milling centers

- Processing up to a length of 3,000 mm

- Processing up to a diameter of 800 mm

- Comprehensive monitoring systems and automated production

- Fully air-conditioned production space and machinery as well as cooling emulsion for continuous process reliability at 22°C

Milling centres and

turning/milling centres

Modern technology, maximum efficiency and the utmost precision: with our milling and turning/milling centres, we manufacture complex components according to individual requirements. Our systems enable complex processing and versatile turning processes, with maximum repeat accuracy guaranteed.

CNC 5-axis simultaneous milling and milling/turning centres

- Processing up to X= 1,300 Y= 1,250 mm

- Processing up to a height of 1,000 mm

- Turning up to a diameter of 1,250 mm

- Comprehensive monitoring systems and automated production using pallet storage

- Fully air-conditioned production space and machinery as well as cooling emulsion for continuous process reliability at 22°C

Premises

for ideal conditions

Our modern premises give our clients, partners, and guests a sense of our passion for precision. With regular investments, for example in ventilation technology or in the photovoltaic system on our building’s roof, we guarantee the perfect conditions for our precision machining services as well as for sustainability.

Learn more about

Keller Precision

Learn more about our traditional company – based in Niederhelfenschwil and run by the third generation of the same family. Our company profile reveals everything you need to know about our values, our history and our team. Dive into the world of precision machining.